|

X-PRIZE team

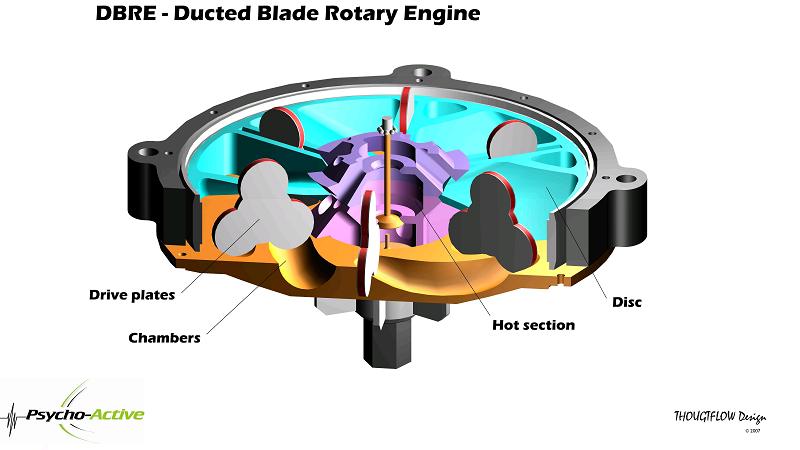

PSYCHO-ACTIVE Ducted

Blade Rotary

Engine (DBRE) Contributed

by THOUGHTFLOW Design |

|

A Turbine for the Masses!

Topography

A rotating disc, sandwiched between

plates having a series

of divot like chambers, carries spinning drive plates with a lobe

engaging each

chamber sequentially. The

sweep of a

lobe through a chamber is analogous to the motion of a piston or

perhaps a

positive displacement turbine blade.

In the illustrated topography, each drive plate lobe accomplishes two cycles of operation simultaneously. Air is drawn in behind one sweeping drive plate while exhaust gases are pushed out in front of it. The following drive plate will enter that chamber 60 degrees later compressing the fresh air while being pushed by the combustion gases of the power stroke.

Fuel Efficiency

1) Thermodynamic- each cycle is a separate

process and can be

optimized for efficiency. The

external

combustion process can be stabilized with a normal fuel/air mix core

[catalytic]

and the power output adjusted with ultra lean bypass air. This provides cooling of

the hot

section, lowers the

combustion

temperature and NOX emissions. The

inter

stage heat energy is usefully recovered in the power stroke. Metering the volume of

combustion gases allowed

to expand in the power stroke effectively lowers the heat wasted in

exhaust. It

is anticipated that a high ‘compression ratio’ can be maintained for

thermodynamic efficiency over all operating parameters.

2) Losses eliminated- some internal losses are inherently reduced by the low part count but more significant is the elimination of pumping loss. Conventional engines are throttled but must still carry enough momentum to complete all four cycles. This forces the engine to work against itself and requires a high speed idle.

In contrast, the DBRE has staggered power strokes meaning there are no dead centers and they overlap the demands of the compression stroke. Idle is unnecessary and pumping losses are gone.

3) Energy conservation- Combustion (and fuel consumption) is restricted to the demand for power. While slowing down, fuel burn is stopped and regenerative braking energy is stored as compression for later use. Captured internally, or with additional external accumulators, it can be released to motor the engine without combustion then fuel can be added as necessary. Self starting.

Wide market potential

The volume displaced

by a Drive plate sweeping through chambers:

Color Code: INTAKE - COMPRESSION - POWER - EXHAUST

Color Code: INTAKE - COMPRESSION - POWER - EXHAUST

Get the Flash Player to see this player.